Pipe Thread Cutting Machine

Since our establishment in 2011, Industrial Machinery Corporation (IMC) has been a trusted name in the industrial machine manufacturing industry. Renowned for producing world-class equipment ...

VIEW MORE

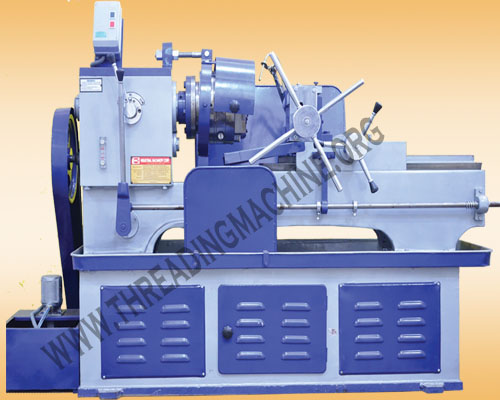

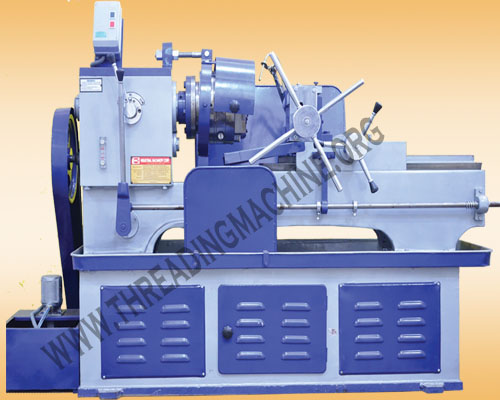

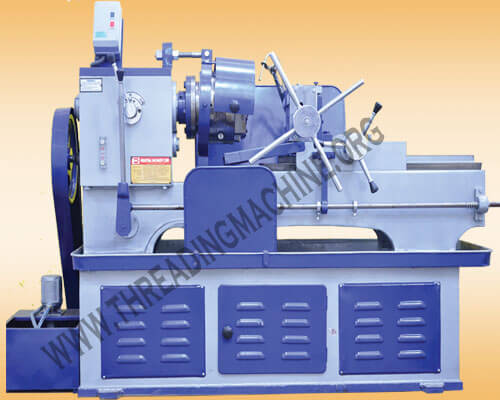

For the last 11 years, since we stepped into this business of industrial machine manufacturing, we have been busy manufacturing the best quality industrial machines and one of such machines that we manufacture here is the rod threading machine. The rod threading machine built by us has been admired by clients worldwide and has made it the most recommended industrial machine. One of the major factors that have made our rod threading machines popular is that we make not only our rod threading machines but all our machines using the best raw materials. All the raw material comes from the most reliable sources, and prior to getting used; all the raw material is passed through the scrutinizing eyes of our quality supervision team for any sort of flaw or defect. Only the best quality raw material is forwarded for manufacturing and the raw material found with even the smallest of the defect is stopped from getting used for the production process. The Rod Threading Machines made by us are the most compact, handy, efficient, compact, and easy to use. Apart from this, there are many other notable features that allow this machine to be the best machine in its niche which has the capacity to give results in form of highly précised and accurately finished high-quality threads despite operating at a very high speed.

For the last 11 years, since we stepped into this business of industrial machine manufacturing, we have been busy manufacturing the best quality industrial machines and one of such machines that we manufacture here is the rod threading machine. The rod threading machine built by us has been admired by clients worldwide and has made it the most recommended industrial machine. One of the major factors that have made our rod threading machines popular is that we make not only our rod threading machines but all our machines using the best raw materials. All the raw material comes from the most reliable sources, and prior to getting used; all the raw material is passed through the scrutinizing eyes of our quality supervision team for any sort of flaw or defect. Only the best quality raw material is forwarded for manufacturing and the raw material found with even the smallest of the defect is stopped from getting used for the production process. The Rod Threading Machines made by us are the most compact, handy, efficient, compact, and easy to use. Apart from this, there are many other notable features that allow this machine to be the best machine in its niche which has the capacity to give results in form of highly précised and accurately finished high-quality threads despite operating at a very high speed.

We have made our Rod Thread Cutting Machine in such a versatile way that it is compatible of producing a wide variety of threads but this variety would entirely depend upon the type of chasers or cutters that is fitted in the rod threading machines at that time. Our rod threading machine is used to thread rods and is broadly used in factories and tool rooms. Commonly this machine works best when it is fixed with HSS Tangential chasers. The rod threading machine that we make runs using the chasing method according to which the machines make the rod to stay at one place and allow the die to rotate around which makes the best quality, most accurate and precise threads around that rod. Let’s have a quick look at the basic specifications and features of the rod threading machine built by industrial machine corporation, the rod threading company, in India:

Here is the list of threads and cuts that our Rod Threading Machines can cut:

| MODEL | 1/4" TO 1" (BED TYPE) | 3/8" TO 1.1/2" (BED TYPE) | 1/2" TO 2.1/2" (BED TYPE) |

| Saddle Movement | 10" | 13" | 22" |

| Spindle Speed Range | 75-140 | 75 -140 | 45 - 90 |

| Number of Spindle Speed | 2 | 2 | 2 |

| Threading Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 60-80 | 60-80 | 70-90 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. |

| Lead Screw | Optional | Optional | Optional |

| Weight (KG) Approx. | 500 | 550 | 990 |

Rod Threading Machine Tangential Chaser

IMC Threading Tangential Chasers are manufactured from imported High Speed Steel which must pass exacting metallurgical standard. Experienced heat treatment with the automatic imported heat treatment plant and imported Testing equipment's, assures that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended.

IMC Threading Chaser is interchangeable. If one Pc. Of a chaser set is damaged & is beyond use. Then same No. pc. Of the other chaser set lying in stock may be used and there will not be any difference in threading performance and the damaged set can be replaced without the necessity of replacing entire set.

Read More.."

Since our establishment in 2011, Industrial Machinery Corporation (IMC) has been a trusted name in the industrial machine manufacturing industry. Renowned for producing world-class equipment ...

VIEW MORE

Our Bar Threading Machine runs on chasing machine and in fact most of our machine runs on the same principle as there are absolutely no chances of any fault or defect in the chasing method. While work ...

VIEW MORE

In the last 7 years, we have been constantly producing the best quality industrial machines using all the experience that we had gained being in the industry for so long. We stepped in the business of ...

VIEW MORE

Ever since we stepped into the business of manufacturing industrial machines by the name of Industrial Machinery corporation in 2011, our only endeavor has been to provide all our clients with the bes ...

VIEW MORE

IMC Steel TMT Chaser Rebar Threading Machines are used to cut threads on TMT steel reinforcement bars used in construction projects. These machines use a chaser system to cut threads into the bars qui ...

VIEW MORE

Electric Conduit Pipe Threading Machine is use to thread the external area of the conduit pipes. IMC Machines highly specialized and can be used solely for industry specific purposes. There are only a ...

VIEW MORE

We offer a wide range of TMT Rebar Threading Machine which is used for site works and it does external threading on TMT bars. The threading is finished after the TMT bar forging process. ...

VIEW MORE