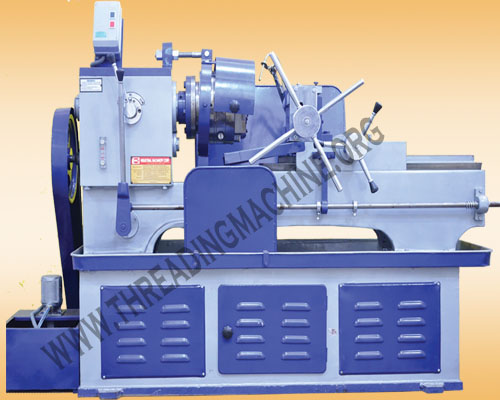

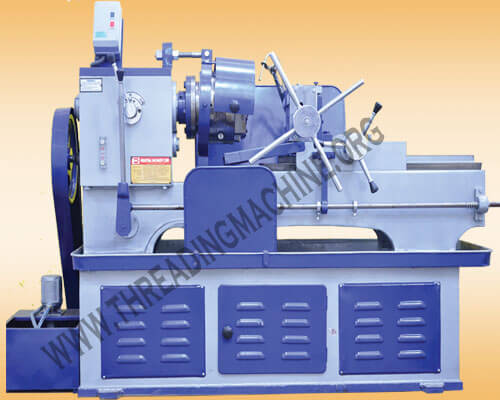

Pipe Thread Cutting Machine

Since our establishment in 2011, Industrial Machinery Corporation (IMC) has been a trusted name in the industrial machine manufacturing industry. Renowned for producing world-class equipment ...

VIEW MORE

Ever since we stepped into the business of manufacturing industrial machines by the name of Industrial Machinery corporation in 2011, our only endeavor has been to provide all our clients with the best quality industrial machines to increase their productivity. Today after 6 years of our formation, we are recognized as one of the most steady and reliable machine manufacturers in India. Through all the experience that we have gained, we have developed a vast range of products related to industrial machines. One such product is Hydraulic Pipe Thread Cutting Machine which is built at our Ludhiana-based industrial machines manufacturing unit. This unit is probably one of the most advanced arenas for manufacturing any kind of industrial machine. The Hydraulic Pipe Threading Machine built by us has been acknowledged as one of the technologically most advanced Hydraulic Pipe Threading Machine. What makes our Hydraulic Pipe Threading Machine so popular and far ahead in sales than Hydraulic Pipe Threading Machines? Well...The answer is simple. We get all our machines and not just the Hydraulic Pipe Threading Machine firstly designed by the international designers so that they are all in accordance with the latest trends prevailing in the national and international market. Apart from being in the blend with the international designs, these designers ensure the design that they create for our Hydraulic Pipe Threading Machine is best suited to the users and operators comfort so that they are able to work on them with absolute ease.

Ever since we stepped into the business of manufacturing industrial machines by the name of Industrial Machinery corporation in 2011, our only endeavor has been to provide all our clients with the best quality industrial machines to increase their productivity. Today after 6 years of our formation, we are recognized as one of the most steady and reliable machine manufacturers in India. Through all the experience that we have gained, we have developed a vast range of products related to industrial machines. One such product is Hydraulic Pipe Thread Cutting Machine which is built at our Ludhiana-based industrial machines manufacturing unit. This unit is probably one of the most advanced arenas for manufacturing any kind of industrial machine. The Hydraulic Pipe Threading Machine built by us has been acknowledged as one of the technologically most advanced Hydraulic Pipe Threading Machine. What makes our Hydraulic Pipe Threading Machine so popular and far ahead in sales than Hydraulic Pipe Threading Machines? Well...The answer is simple. We get all our machines and not just the Hydraulic Pipe Threading Machine firstly designed by international designers so that they are all in accordance with the latest trends prevailing in the national and international market. Apart from being in the blend with international designs, these designers ensure the design that they create for our Hydraulic Pipe Threading Machine is best suited to the user's and operators' comfort so that they are able to work on them with absolute ease.

The popularity of our Hydraulic Pipe Thread Cutting Machine is also the result of the efficiency, easy and high-quality performance, this machine provides to its operator while in work. All the raw material used by for the manufacturing of Hydraulic Pipe Threading Machine is drawn from our age-old suppliers who supply to us, only the best quality raw material. Upon the arrival of the raw material, our quality supervision team checks every part of the raw material for any sort of defect and imperfection. If there is any sort of flaw or fault, that part is removed immediately. This makes sure that the Hydraulic Pipe Threading Machine is made so strong that it is able to work for long hours without any sort of wear and tear or system break down. Post-production again our quality supervision team checks that our Hydraulic Pipe Threading Machine is perfectly built without any production defect. This team makes sure that all the electric, as well as safety features, are properly installed which makes this Hydraulic Pipe Thread Cutting Machine. Hydraulic Pipe Threading Machine has a hydraulic cylinder lead screw box nut engaging, one hydraulic pipe clamping cylinder and one hydraulic cylinder for die-head opening with micro switches with automation with the control panel. Our Hydraulic Pipe Thread Cutting Machine could be used to draw a big variety of threads on the pipe. Following is the list of names of cuts that our Hydraulic Pipe Threading Machine can cut:

| Model | 1/2" to 2.1/2" (Pillar Type) | 1" to 4" (Pillar Type) | 2.1/2" to 6" (Pillar Type) | 4" to 8" (Pillar Type) |

| Saddle Movement | 12" – 16" | 10" – 12" | 8" | 8" |

| Spindle Speed Range | 60-90-120 | 40-75-115 | 25-50 | 25-50 |

| Number of Spindle Speed | 3 | 3 | 2 | 2 |

| Threading Capacity | 1/2" to 2.1/2" | 1" to 4" | 2.1/2" to 6" | 4" to 8" |

| Production per Hour | 70-90 | 35-40 | 20-25 | 15-20 |

| H.P. Power Require (960 RPM) | 7.5 H.P. | 12.5 H.P. | 15 H.P. | 20 H.P. |

| Lead Screw | Automatic | Automatic | Automatic | Automatic |

| Weight (KG) Approx. | 990 | 1600 | 1900 | 2500 |

Hydraulic Pipe Threading Machine Tangential Chaser

IMC Tangential Chasers are manufactured from imported High Speed Steel which must pass exacting metallurgical standard. Experienced heat treatment with the automatic imported heat treatment plant and imported Testing equipment, assures that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended.

IMC Chaser are interchangeable. If one Pc. Of a chaser set is damaged & is beyond use. Then same No. pc. Of the other chaser set lying in stock may be used and there will not be any difference in threading performance and the damaged set can be replaced without the necessity of replacing entire set.

Read More.

Since our establishment in 2011, Industrial Machinery Corporation (IMC) has been a trusted name in the industrial machine manufacturing industry. Renowned for producing world-class equipment ...

VIEW MORE

Our Bar Threading Machine runs on chasing machine and in fact most of our machine runs on the same principle as there are absolutely no chances of any fault or defect in the chasing method. While work ...

VIEW MORE

In the last 7 years, we have been constantly producing the best quality industrial machines using all the experience that we had gained being in the industry for so long. We stepped in the business of ...

VIEW MORE

For the last 11 years, since we stepped into this business of industrial machine manufacturing, we have been busy manufacturing the best quality industrial machines and one of such machines that we ma ...

VIEW MORE

IMC Steel TMT Chaser Rebar Threading Machines are used to cut threads on TMT steel reinforcement bars used in construction projects. These machines use a chaser system to cut threads into the bars qui ...

VIEW MORE

Electric Conduit Pipe Threading Machine is use to thread the external area of the conduit pipes. IMC Machines highly specialized and can be used solely for industry specific purposes. There are only a ...

VIEW MORE

We offer a wide range of TMT Rebar Threading Machine which is used for site works and it does external threading on TMT bars. The threading is finished after the TMT bar forging process. ...

VIEW MORE