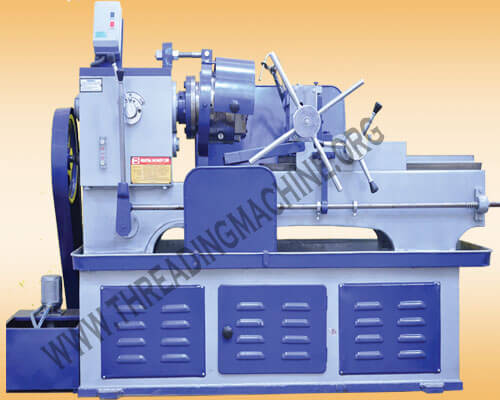

Pipe Thread Cutting Machine

Since our establishment in 2011, Industrial Machinery Corporation (IMC) has been a trusted name in the industrial machine manufacturing industry. Renowned for producing world-class equipment ...

VIEW MORE

Our Bar Threading Machine runs on chasing machine and in fact most of our machine runs on the same principle as there are absolutely no chances of any fault or defect in the chasing method. While working on chasing method, the Bar Threading Machine makes the pipe to stay stable at one place and allows the die head to rotate around it precisely producing accurately drawn threads.

VIEW SPECIFICATIONSSince our formation, we have specialized in manufacturing finest quality Bar Threading Machines. The Bar Thread Cutting Machine that we manufacture have all the qualities that have made our machines, the most used, recommended as well as searched Bar Threading Machine. Only the finest quality raw material is used to build not only our Bar Threading Machine but our machines and this ensures us all our machines will be sturdy, vigorous and strong enough to face the wears and tears arising in factories and tool-rooms. The Bar Threading Machines made by us is specially designed and manufactured to provide the maximum of working hours to the buyers and imposing minimum of maintenance cost. Our Bar Thread Cutting Machine runs on chasing machine and in fact, most of our machine run on the same principle as there are absolutely no chances of any fault or defect in the chasing method. While working on the chasing method, the Bar Thread Cutting Machine makes the pipe to stay stable at one place and allows the die head to rotate around it precisely producing accurately drawn threads. Following are the features of Steel Bar Thread cutting Machines manufactured by us at our Ludhiana unit:

Following are the names of various parts and components that assemble together to make the finest quality Steel Bar Thread Cutting Machine:

| Model | 1/4"to 1" (Bed Type) | 3/8" to 1.1/2" (Bed Type) | 1/2" to 2.1/2" (Bed type) |

| Saddle Movement | 10? | 13? | 22? |

| Spindle Speed Range | 75-140 | 75-140 | 45-90 |

| Number of Spindle Speed | 2 | 2 | 3 |

| Threading Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 60-80 | 60-80 | 70-90 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. |

| Lead Screw | Optional | Optional | Optional |

| Weight (KG) Approx. | 500 | 550 | 990 |

Bar Thread Cutting Machine Tangential Chaser

IMC Tangential Chasers are manufactured from imported High-Speed Steel which must pass exacting metallurgical standard. Experienced heat treatment with the automatically imported heat treatment plant and imported Testing equipment's, assures that they will perform satisfactorily in service and produce quality threads within the tolerance for which they ware intended.

IMC Chaser is interchangeable. If one Pc. Of a chaser, set is damaged & is beyond use. Then same No. pc. Of the other chaser set lying in stock may be used and there will not be any difference in threading performance and the damaged set can be replaced without the necessity of replacing the entire set.

Read More..

Since our establishment in 2011, Industrial Machinery Corporation (IMC) has been a trusted name in the industrial machine manufacturing industry. Renowned for producing world-class equipment ...

VIEW MORE

In the last 7 years, we have been constantly producing the best quality industrial machines using all the experience that we had gained being in the industry for so long. We stepped in the business of ...

VIEW MORE

Ever since we stepped into the business of manufacturing industrial machines by the name of Industrial Machinery corporation in 2011, our only endeavor has been to provide all our clients with the bes ...

VIEW MORE

For the last 11 years, since we stepped into this business of industrial machine manufacturing, we have been busy manufacturing the best quality industrial machines and one of such machines that we ma ...

VIEW MORE

IMC Steel TMT Chaser Rebar Threading Machines are used to cut threads on TMT steel reinforcement bars used in construction projects. These machines use a chaser system to cut threads into the bars qui ...

VIEW MORE

Electric Conduit Pipe Threading Machine is use to thread the external area of the conduit pipes. IMC Machines highly specialized and can be used solely for industry specific purposes. There are only a ...

VIEW MORE

We offer a wide range of TMT Rebar Threading Machine which is used for site works and it does external threading on TMT bars. The threading is finished after the TMT bar forging process. ...

VIEW MORE