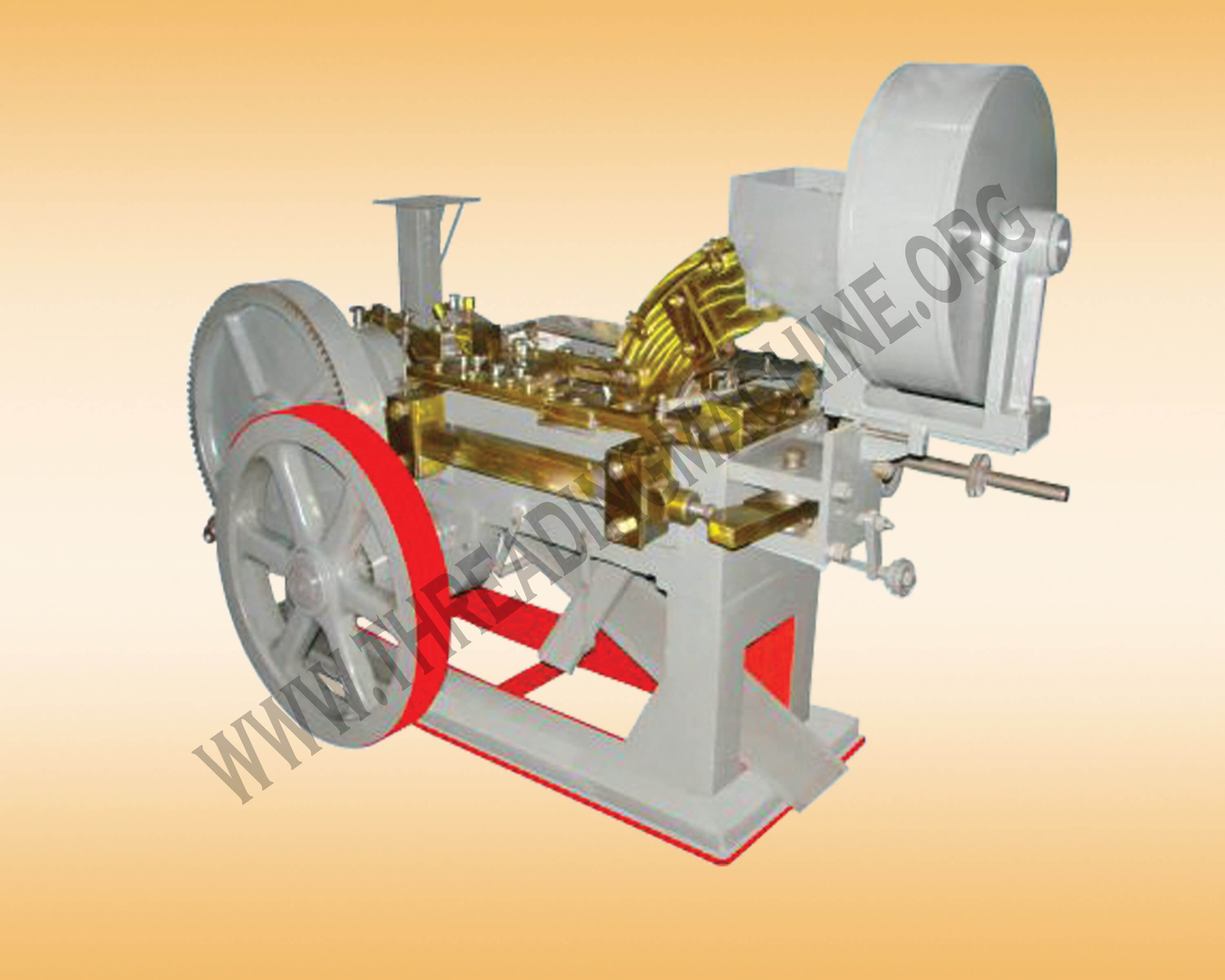

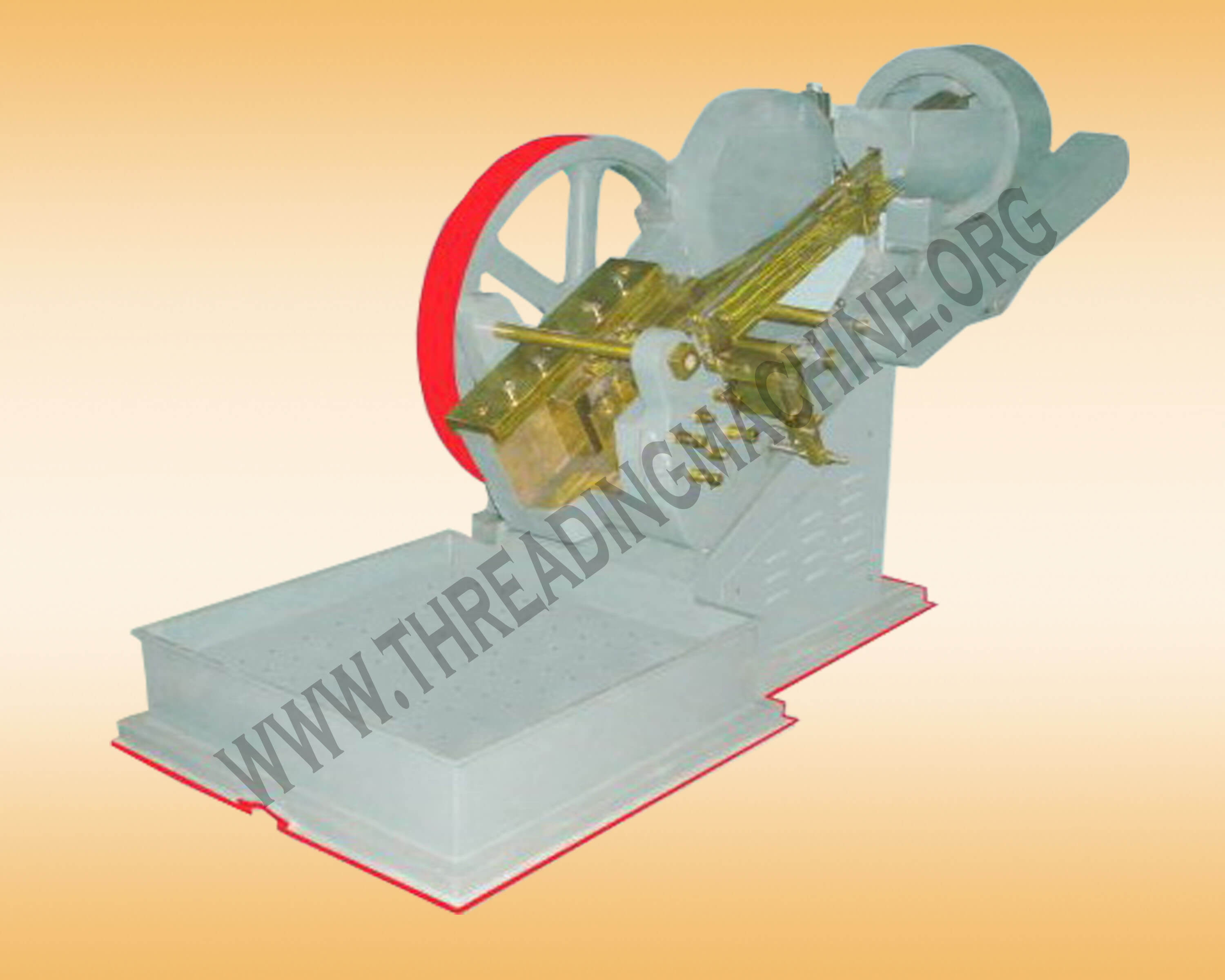

Automatic Cold Thread Rolling Machine

Ever since we landed in the business of industrial machine manufacturing in 2011, we have been working rigorously to serve all our clients and buyers with the best of industrial machine. We are not reticent on working 24 hours a day a seven days a month to make or industrial machines and dress them with all the qualities that we have been renowned for. This is probably the reason why in a very short span of just 6 years, we have got the tag of being one of the best industrial machine manufacturing companies of India. Through all the experience that we have gained in this field we have developed a proficiency of designing a wide range of product and one such product is the flat die thread rolling machine that we specialize in constructing. For more than six years now we have been producing flat die thread rolling machine and developed huge expertise in making and exporting of 2 and 3 roller thread rolling machines in both variants of mechanical as well as hydraulic edition.

Over the years, Flat Die Thread Rolling Machine has proven itself to be a wonderful machine for assembling of threads, worms, knurls, serrations and many others. Being for more than 6 years in this business clears the fact that that we have all the necessary technical knowledge and expertise to build flat die thread rolling machine as per the requirement and specifications mentioned by the client while placing the order. Following are the standard accessories that we provide to all our clients with the customized or non-customized form of flat die thread rolling machine that we manufacture here at our manufacturing base located in Ludhiana:

- Vibratory hopper feeder or rotary drum type hopper feeder provided as per requirement of the buyer.

- One set of dies for one standard size.

- One set of tools and one set of special adjusting tools.

And mentioned beneath are the optional accessories that are given by us to all our buyers of this flat die thread rolling machine. It should be noted that these are not a mandatory part of the machine but a client can get them installed on their machines as per their customization requirement and preferences:

- Sliding hopper feeder (stairs type) provided at additional cost as per request of the buyer.

- Drum type chips separator, roller type scrapping thread chips are provided on request.

Apart from this, while making our Flat die thread rolling machine, we make every assurance that we are using the best of technology, upgraded software and newest technical know how to make it and are designing and manufacturing flat die thread rolling machines which are consistent, competent, attuned, hard-wearing, trustworthy and handy flat die thread rolling machine. All the raw material that is to be used for making of our Flat Die Thread Rolling Machine is driven from best of resources and always made sure by our quality vigilance team that the raw material is perfectly fit for use without even a tinge of defect or imperfectness. The Flat Die Thread Rolling Machine made by us has the potential to produce both large and small batches of all kinds.

Flat die thread rolling machine Specifications:

| Model No. | FDTRM-1 | FDTRM-2 | FDTRM-3 | FDTRM-4 | FDTRM-5 | FDTRM-6 |

| Min. Max. Dia Can Be Rolled | 1/16"x1/4" | 1/8"x1/2" | 1/8"x 1/2" | 1/4"x5/8" | 1/4"x3/4" | 1/4" x7/8" |

| Max. Length of Thread | 2" | 2.1/2" | 3" | 3" | 4" | 4" |

| Dimension of Fixed Dia | 3"x2"x1" | 5"x2.1/2"x1" | 5"x3"x1" | 6"x3"x1" | 6"x4"x1" | 7"x4"x1" |

| Dimension of Moving Dia | 4"x2"x1" | 6"x2.1/2"x1" | 6"x3"x1" | 7"x3"x1" | 7"x4"x1" | 8"x4"x1" |

| Production in Pieces Per Minute | 80 | 60 | 60 | 50 | 30 | 30 |

| Power Required in H.P. | 2 | 3 | 5 | 7.5 | 10 | 15 |